Innovations in Technology for Colorant Application

Introduction

Color is more than just a visual element; it’s a powerful tool that can influence mood, perception, and behavior. From textiles and packaging to automotive and electronics, colorants play a crucial role across various industries. With the rapid advancements in technology, the methods of applying colorants have evolved significantly, offering greater efficiency, precision, and sustainability.

Historical Background of Colorant Application

Early Methods of Colorant Application

In ancient times, natural dyes derived from plants, minerals, and insects were used to color textiles and other materials. These methods were labor-intensive and often produced inconsistent results. Despite their limitations, these early techniques laid the groundwork for the development of more advanced methods.

Industrial Revolution and Colorant Technology

The Industrial Revolution marked a turning point in colorant application. The invention of synthetic dyes and mechanized processes revolutionized the industry, allowing for mass production and more consistent quality. This period saw the birth of many techniques that are still in use today, albeit in more advanced forms.

Modern Techniques in Colorant Application

Digital Printing

Digital printing has transformed the way colorants are applied, particularly in the textile and packaging industries. This technology allows for high-resolution, customizable prints, and is ideal for short runs and prototypes.

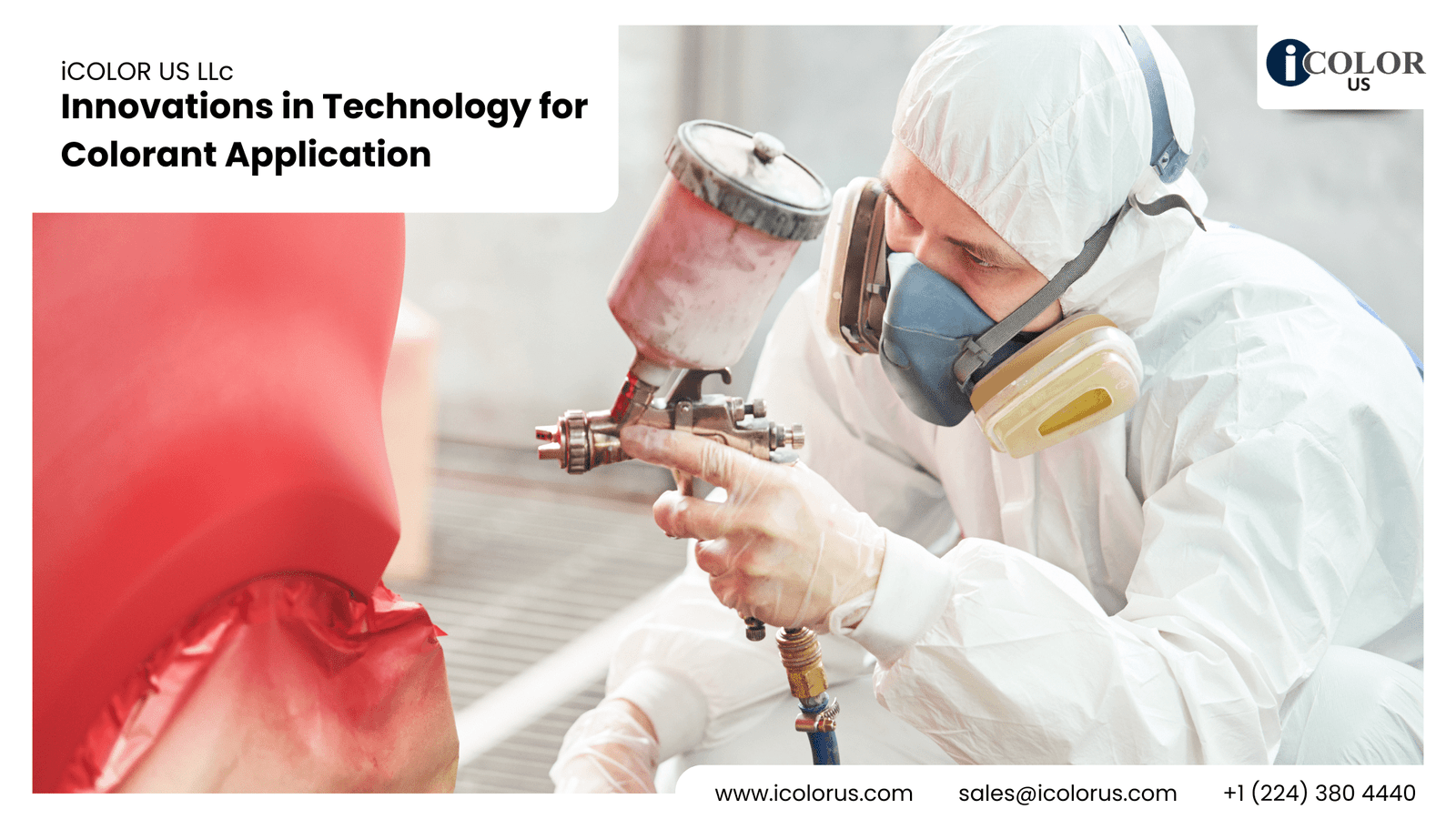

Spray Application

Spray application is widely used in industries like automotive and furniture. This method provides a smooth, even coat of colorant and is efficient for large surfaces.

Automated Dyeing Machines

Automated dyeing machines have brought unprecedented efficiency and precision to the textile industry. These machines can handle large volumes and ensure uniform color application.

Digital Printing Technology

Advantages of Digital Printing

Digital printing offers several advantages over traditional methods. It allows for greater customization, faster turnaround times, and reduced waste. Additionally, it can produce complex designs with high precision.

Types of Digital Printing

There are various types of digital printing, including inkjet and laser printing. Each type has its unique advantages and is suited to different applications.

Applications in Textile and Packaging Industries

In the textile industry, digital printing is used for creating detailed fabric patterns and designs. In packaging, it is used for printing labels, cartons, and flexible packaging.

Spray Application Technology

Principles of Spray Application

Spray application involves the use of specialized equipment to atomize colorant and apply it to a surface. This method ensures a uniform coat and can be used for a variety of materials.

Benefits in Automotive and Furniture Industries

In the automotive industry, spray application is used for painting vehicles, providing a smooth and durable finish. In the furniture industry, it is used for applying stains and finishes to wood and other materials.

Environmental Impact

Spray application can have environmental benefits, such as reducing waste and emissions. However, it is essential to use eco-friendly materials and proper ventilation to minimize any negative impact.

Automated Dyeing Machines

How Automated Dyeing Works

Automated dyeing machines use advanced technology to control the dyeing process, ensuring consistent results. These machines can adjust parameters like temperature, pressure, and dye concentration to achieve the desired color.

Efficiency and Precision in the Textile Industry

Automated dyeing machines are highly efficient, capable of processing large volumes of fabric quickly. They also offer precise control, ensuring uniform color application across batches.

Case Studies of Leading Companies

Several leading companies have adopted automated dyeing technology to improve their processes. These companies have reported significant gains in efficiency and quality, setting new standards in the industry.

Innovative Colorant Materials

Introduction of Nanotechnology in Colorants

Nanotechnology has opened up new possibilities for colorants. By incorporating nanoparticles, manufacturers can enhance color properties and create new effects.

Sustainable and Eco-Friendly Colorants

With increasing awareness of environmental issues, there is a growing demand for sustainable colorants. Innovations in this area focus on using natural and biodegradable materials.

Smart Colorants and Their Applications

Smart colorants can change color in response to external stimuli, such as temperature or light. These materials have exciting applications in textiles, packaging, and more.

Nanotechnology in Colorants

How Nanoparticles Enhance Colorant Properties

Nanoparticles can improve the durability, brightness, and stability of colorants. They can also create unique effects, such as iridescence and color-shifting.

Applications in Various Industries

Nanotechnology-enhanced colorants are used in a wide range of industries, including textiles, automotive, cosmetics, and electronics. They offer superior performance and new possibilities for design.

Future Prospects

The future of nanotechnology in colorants looks promising, with ongoing research focused on developing even more advanced materials. These innovations have the potential to revolutionize the way we use color.

Sustainable and Eco-Friendly Colorants

Importance of Sustainability in Modern Manufacturing

Sustainability has become a key consideration in manufacturing, driven by consumer demand and regulatory requirements. Using eco-friendly colorants is a crucial part of this effort.

Innovations in Eco-Friendly Colorant Production

Recent innovations in colorant production include the use of natural dyes, biodegradable materials, and water-saving technologies. These advancements help reduce the environmental impact of manufacturing.

Examples of Sustainable Practices

Companies around the world are adopting sustainable practices, such as using recycled materials, reducing water usage, and minimizing waste. These efforts contribute to a more sustainable future.

Smart Colorants

Definition and Characteristics

Smart colorants are materials that can change color in response to external conditions, such as temperature, pH, or light. They are made using advanced chemical formulations.

Applications in Textiles and Beyond

In textiles, smart colorants can create fabrics that change color with temperature or UV exposure. Beyond textiles, they are used in packaging, security, and medical applications.

Future Potential of Smart Colorants

The potential for smart colorants is vast, with ongoing research exploring new applications and materials. These innovations could lead to new products and functionalities in various industries.

Technological Innovations in Application Equipment

Advanced Machinery for Colorant Application

Modern machinery for colorant application includes advanced printers, spray systems, and dyeing machines. These machines offer greater precision and efficiency.

Integration of AI and Machine Learning

AI and machine learning are transforming colorant application by optimizing processes, predicting maintenance needs, and improving quality control. These technologies make production more efficient and reliable.

Impact on Production Efficiency

The integration of advanced technology in colorant application equipment has significantly improved production efficiency. Companies can produce higher quality products at a lower cost and with less waste.

AI and Machine Learning in Colorant Application

Role of AI in Optimizing Processes

AI can analyze large amounts of data to optimize colorant application processes. It can adjust parameters in real-time to achieve the best results, reducing waste and improving quality.

Predictive Maintenance and Quality Control

Machine learning algorithms can predict when maintenance is needed, preventing downtime and extending the life of equipment. They can also monitor quality, ensuring consistent results.

Real-World Examples

Many companies are already using AI and machine learning in their colorant application processes. These technologies have helped them improve efficiency, reduce costs, and enhance product quality.

Challenges in Adopting New Technologies

Technological Barriers

Adopting new technologies can be challenging due to the complexity of the equipment and the need for specialized knowledge. Companies must invest in training and support to overcome these barriers.

Cost and Investment Considerations

New technologies often require significant investment, which can be a barrier for smaller companies. However, the long-term benefits, such as increased efficiency and reduced waste, can justify the initial cost.

Training and Skill Development

To effectively use new technologies, companies must ensure their workforce is properly trained. This requires ongoing education and support to keep up with the latest advancements.

Future Trends in Colorant Application Technology

Predictions for the Next Decade

The next decade is likely to see continued innovation in colorant application technology. Advances in digital printing, nanotechnology, and smart colorants will drive the industry forward.

Emerging Technologies on the Horizon

Emerging technologies, such as 3D printing with colorants and advanced AI algorithms, hold promise for the future. These innovations could revolutionize the way colorants are applied.

Industry Expert Insights

Industry experts predict that sustainability and efficiency will be the key drivers of future innovations. Companies that embrace these trends will be well-positioned for success.

Conclusion

The field of colorant application technology is rapidly evolving, driven by innovations in digital printing, nanotechnology, and AI. These advancements offer significant benefits, including increased efficiency, precision, and sustainability. As the industry continues to innovate, the future of colorant application looks bright and full of exciting possibilities.

FAQs

What are the benefits of digital printing over traditional methods?

Digital printing offers greater customization, faster turnaround times, and reduced waste compared to traditional methods. It also allows for high-resolution, complex designs.

How does nanotechnology improve colorant performance?

Nanotechnology enhances colorant properties by improving durability, brightness, and stability. It can also create unique effects, such as iridescence and color-shifting.

What are some examples of sustainable colorants?

Sustainable colorants include natural dyes, biodegradable materials, and water-saving technologies. These innovations help reduce the environmental impact of manufacturing.

How is AI changing the colorant application industry?

AI optimizes processes, predicts maintenance needs, and improves quality control in colorant application. This leads to greater efficiency, reduced costs, and enhanced product quality.

What are the main challenges in adopting new colorant technologies?

Challenges include technological barriers, cost and investment considerations, and the need for training and skill development. Overcoming these challenges requires investment in education and support.