Colorants in the Cable Industry – Introduction

The cable industry, a critical backbone of modern infrastructure, spans across various sectors from telecommunications to power distribution. Amidst the technical specifications and performance standards, one element often goes unnoticed – colorants. These are not merely for aesthetic appeal but serve several crucial roles in the functionality, safety, and efficiency of cables.

Understanding Cable Colorants

Colorants, substances used to impart color to materials, are integral in the cable industry. They come in various forms, including dyes and pigments, each with unique properties suitable for different applications. In the cable industry, colorants ensure that cables are easily identifiable and meet specific industry standards.

History of Colorants in Cable Manufacturing

The use of colorants in cables dates back to the early 20th century. Initially, basic color schemes were used primarily for identification. Over time, the technology and materials used in colorants have evolved significantly, leading to the sophisticated and standardized systems we have today.

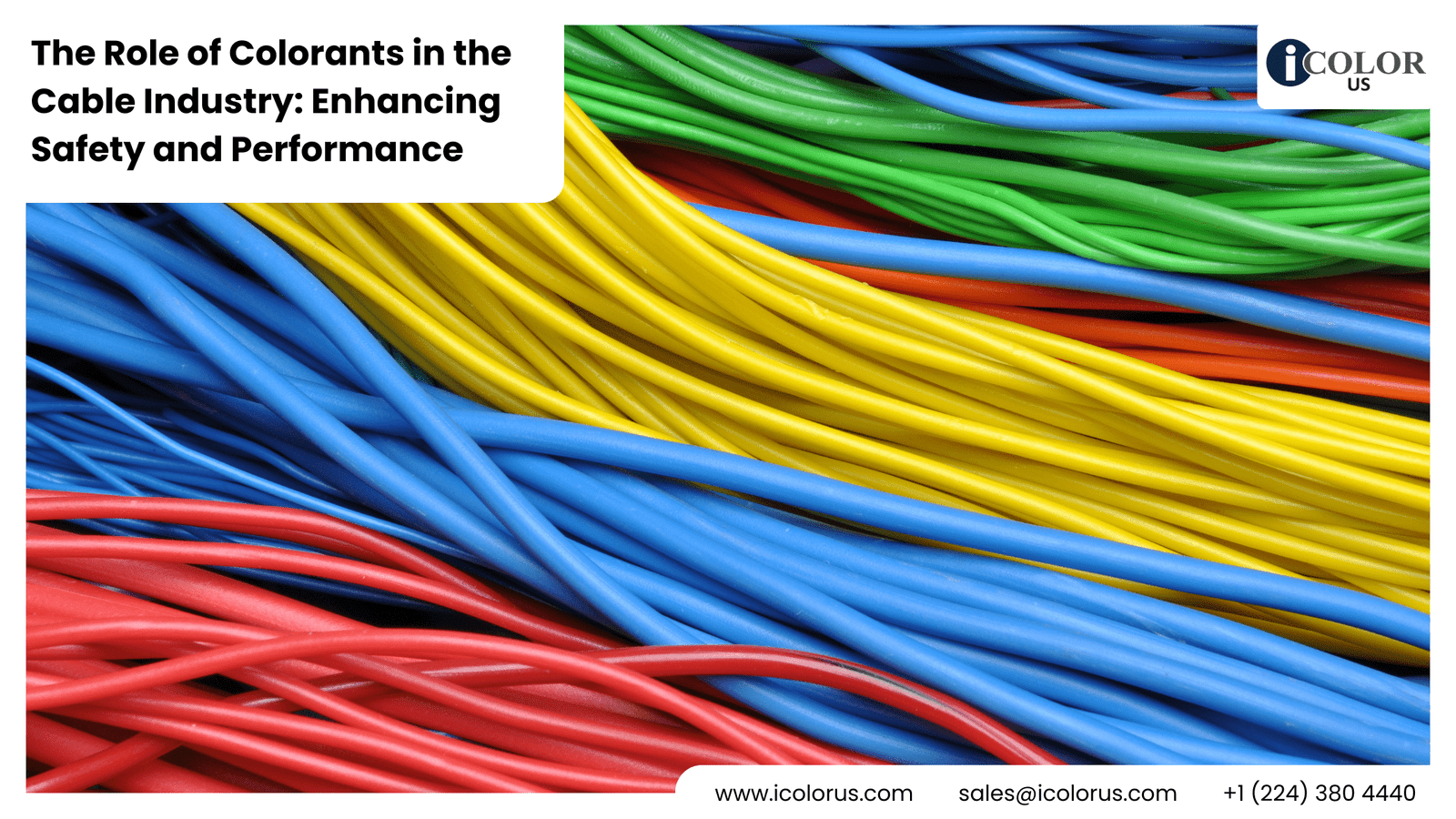

Types of Cables and Their Color Coding

Electrical Cables

In electrical installations, color coding is crucial for safety. It helps in identifying different conductors and their purposes, such as live, neutral, and earth wires. Standard colors are often mandated by regional and international regulations.

Communication Cables

Communication cables, including those used for internet and telephone services, also rely on color coding. This facilitates the organization and maintenance of complex networks, ensuring that signals are correctly routed and managed.

Specialty Cables

Specialty cables, used in specific industries like aviation and marine, have unique color coding requirements that meet stringent regulatory standards. These codes ensure operational efficiency and safety in high-risk environments.

Importance of Color Coding in Cables

Safety and Identification

Color coding significantly enhances safety by providing clear identification of cable functions, reducing the risk of electrical accidents and improving the efficiency of troubleshooting and maintenance.

Industry Standards

Various standards organizations, such as the International Electrotechnical Commission (IEC) and the National Electrical Code (NEC), prescribe specific color codes for cables. Compliance with these standards is essential for legal and operational reasons.

Materials Used in Cable Colorants

Organic vs. Inorganic Colorants

Colorants can be organic or inorganic. Organic colorants, derived from carbon-based molecules, offer vibrant colors but may lack stability. Inorganic colorants, made from mineral compounds, are more stable and durable, making them ideal for industrial applications.

Common Materials

Common materials used in cable colorants include titanium dioxide for white, carbon black for black, and various metal oxides for other colors. Each material is selected based on its properties and suitability for the specific application.

Manufacturing Process of Colored Cables

Extrusion Process

The most common method of manufacturing colored cables is through extrusion, where colorants are mixed with the base material and extruded into the desired cable shape. This process ensures uniform color distribution and consistency.

Quality Control

Quality control in the manufacturing process involves rigorous testing to ensure that the colorants are evenly distributed and meet the required standards for performance and safety.

Environmental Impact of Cable Colorants

Eco-friendly Colorants

With growing environmental concerns, the cable industry is increasingly adopting eco-friendly colorants. These colorants are free from heavy metals and other toxic substances, reducing their environmental footprint.

Regulations and Compliance

Regulatory bodies are imposing stricter controls on the use of hazardous substances in cable colorants. Compliance with these regulations is essential for manufacturers to avoid legal penalties and market restrictions.

Technological Advances in Cable Colorants

Innovations in Material Science

Advances in material science have led to the development of colorants that are more durable, environmentally friendly, and cost-effective. These innovations enhance the overall performance and sustainability of cables.

Future Trends

Future trends in cable colorants include the development of smart colorants that can change color based on environmental conditions, providing real-time monitoring capabilities.

Challenges in the Use of Colorants

Technical Challenges

Technical challenges include ensuring the stability and compatibility of colorants with different cable materials and maintaining color consistency under various environmental conditions.

Market Challenges

Market challenges involve balancing the cost of high-quality colorants with the competitive pricing demands of the cable industry.

Case Studies

Successful Implementations

Several case studies highlight successful implementations of innovative colorants in cable manufacturing. These cases demonstrate the benefits of using advanced colorants in improving cable performance and safety.

Lessons Learned

Lessons learned from these case studies emphasize the importance of thorough testing and adherence to standards in the development and use of cable colorants.

Best Practices for Using Colorants in Cable Manufacturing

Selection of Colorants

Selecting the right colorants involves considering factors such as material compatibility, regulatory compliance, and environmental impact. Manufacturers must choose colorants that meet their specific requirements without compromising on quality.

Application Techniques

Proper application techniques are crucial for ensuring the effectiveness of colorants. This includes precise mixing, controlled extrusion processes, and rigorous quality control measures.

Role of Colorants in Cable Durability and Performance

Impact on Longevity

The right colorants can significantly enhance the durability and longevity of cables. They provide resistance to UV radiation, chemicals, and other environmental factors that can degrade cable materials.

Performance Under Different Conditions

Colorants also affect the performance of cables under various conditions. High-quality colorants ensure that cables maintain their functionality and reliability in extreme temperatures, high humidity, and other challenging environments.

Economic Aspects of Cable Colorants

Cost Implications

While high-quality colorants may increase the initial cost of cable manufacturing, they offer long-term benefits in terms of durability and reduced maintenance costs, making them a cost-effective choice.

Market Demand

Market demand for advanced colorants is growing as industries recognize the benefits of improved performance and environmental compliance. This trend is driving innovation and competition in the colorants market.

Conclusion

Colorants play a vital role in the cable industry, far beyond mere aesthetics. They are essential for safety, identification, and compliance with industry standards. With technological advances and a growing emphasis on environmental sustainability, the future of cable colorants looks promising. As the industry continues to evolve, manufacturers must stay informed about the latest trends and best practices to ensure the optimal performance and safety of their products.

FAQs

What are the most common colorants used in cables? The most common colorants used in cables include titanium dioxide for white, carbon black for black, and various metal oxides for other colors.

How do colorants affect the performance of cables? Colorants enhance the performance of cables by providing UV resistance, chemical resistance, and durability under various environmental conditions.

Are there any eco-friendly options for cable colorants? Yes, eco-friendly colorants are available that are free from heavy metals and toxic substances, reducing their environmental impact.

Why is color coding important in electrical cables? Color coding in electrical cables is crucial for safety and identification, helping to prevent electrical accidents and facilitating maintenance.

What are the future trends in cable colorants? Future trends include the development of smart colorants that can change color based on environmental conditions, offering real-time monitoring capabilities.